Process

Custom rubber solutions start with a unique problem in your business. Chemical corrosion, damage caused by impact and abrasion, excessive noise, or vibration issues - just to name a few. Your unique issue will be the first step in creating a custom solution. Simply contact us with information about your problem (it can be as simple as sending us a sketch) and allow us to take the reigns in determining the best rubber application for you.

Options

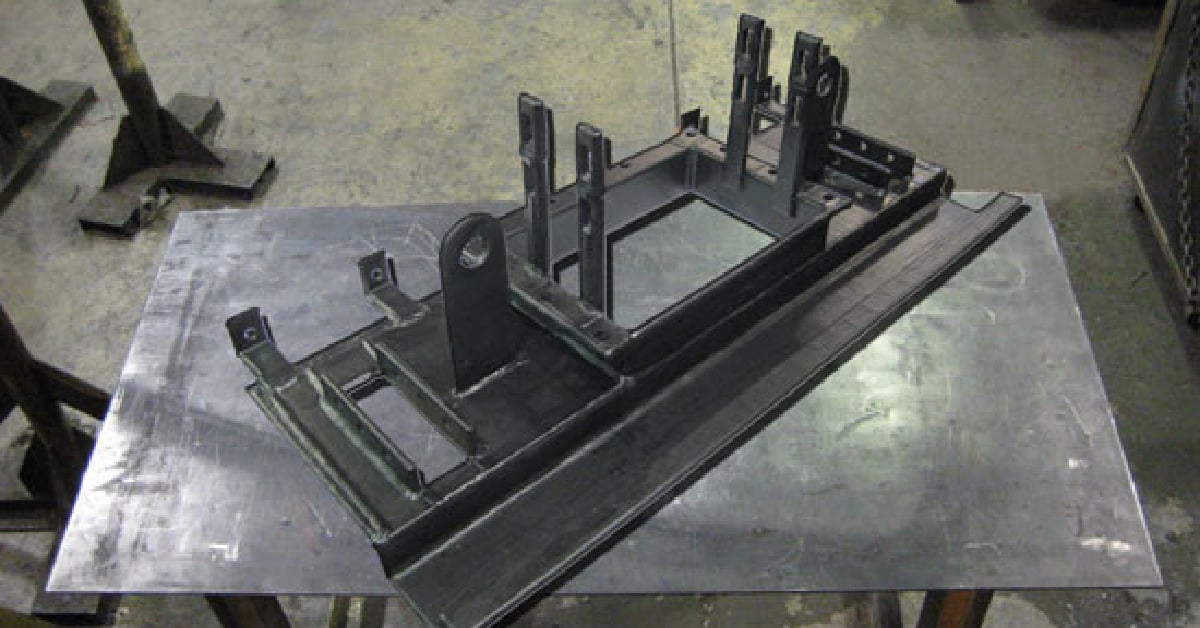

We see the big picture and love stepping outside of the box to help you solve your abrasion, corrosion, and impact issues. We’ve created custom solutions for a wide variety of industries; agriculture, manufacturing, mining & aggregate, and the list goes on. This brief list of some of our custom rubber products will help you get an idea of what we are capable of:

- Forklift clamp pads – for box and paper roll carriers; relining your worn clamp pads is much more cost-effective than purchasing a brand new set

- Forklift forks – coating the forks to protect the products that are being moved; coated pipe, boats, painted products, etc.

- Polishing disks – used for glass polishing (up to 48” diameter). Rubber tampers for asphalt machinery

- Gaskets – for special machinery, largest to date: 8′ wide x 20′ long

- Pump housings – internal linings for slurry pumps or dredge pumps

- Impellers – for slurry or dredge type pumps

- Fan housings – for chemical plants or systems moving air with corrosive atmospheres

- Chutes – sand chutes, grain spouts, transitions

- Hoppers – sand, gravel, concrete, or even hard candy for wear and noise control

- Impact pads – various sizes, shapes, and thickness

- Scraper blades – snowplows, squeegees, street sweeps

- Discharge Chutes – unloading or loading grain, feed, fertilizer, or any dust creating product into or out of storage bins, rail cars, or trucks

Timeframe

Perhaps you’re hesitant to inquire about custom rubber products because you’re worried it will be a long, drawn-out process. We understand the pinch that you’re in, and how necessary your equipment is to the function of your business. After initially reaching out to us, you can expect a quote within two business days. When the project begins, we will provide you with a completion date. We take pride in the fact that we’re always on time, and you can count on that!

There are so many possible applications for a custom rubber project, the options are endless! Give us a call to learn how your specific operation can be improved and maximized with the help of custom rubber products.