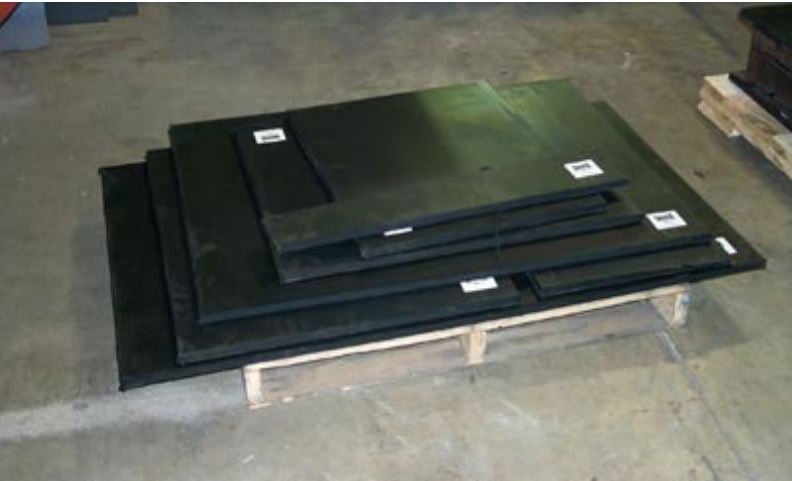

In today's world of advanced and custom packaging, clamp pads have become an essential accessory for every forklift. They play a vital role in minimizing damage to delicate cargo like boxes, crates, and paper rolls, while providing the necessary grip for safe and efficient material handling. The demand for clamp pads is undeniable, but here's what many manufacturers aren't telling you – you don't have to buy new ones each time they wear out.

What Manufacturers Keep Quiet About Your Forklift – The Unspoken Truth

Topics: Clamp Pads

Time-Saving Solutions for Equipment Wear and Tear

In the world of manufacturing and industry, daily wear and tear on machines and equipment is an unavoidable reality. However, the costs associated with abrasion, impact, and corrosion-related breakdowns can be substantial. Not only does production come to a halt, but the expenses for repairs and downtime can quickly escalate.

Topics: Clamp Pads, HawkPad, Tuff Tube

Exploring the Timeless Power of Natural Rubber in Modern Industries

When you think of rubber, the familiar image of synthetic rubber might come to mind, particularly Styrene-Butadiene Rubber (SBR) that dominates manufacturing today. However, the original contender, natural rubber, still holds its ground in industries like chemical, mining, fertilizer, transportation, and environment. In this blog, we'll delve into the enduring relevance of natural rubber and its crucial role in various sectors.

Topics: Rubber Products, Rubber Coatings, Rubber

Recovering Clamp Pads: The Cost-Effective Solution for Tough Applications

When it comes to material handling in warehouses, clamp pads are essential tools. They provide the extra grip needed to minimize material damage during material handling. Dealing with worn-out clamp pads can be a headache. Replacement costs are high, and the downtime during shipping and potential fitting issues can result in lost productivity and wasted time. Fortunately, Sioux Rubber & Urethane offers a better solution: recovering your existing clamp pads. Let's explore why recovery is the superior choice.

The Power of Rubber Solutions: Enhancing Performance and Efficiency in Manufacturing

Rubber products play a vital role in various industries, providing crucial solutions for improving performance, productivity, and efficiency. In this blog post, we will explore some rubber solutions we offer and delve into how they can transform your manufacturing processes. From wear-resistant materials to custom-molded parts, let's discover the power of rubber in driving success!

Extreme weather is nothing new for Midwesterners. Rain, snow, sun, or floods, we must be ready for almost anything in the Midwest. And our machinery needs to be, too. With below-freezing temperatures in the winter, machinery is often the first victim to heavy snow and freezing temps. Fortunately, Sioux Rubber & Urethane has you and your machinery covered! With high-quality urethane products, we keep your equipment tougher than the weather and lasting longer.

Topics: Urethane Coatings, Urethane, polyurethane

What is the Toughest Rubber Type?

The term “tough” is often used to describe something as being long-lasting and resilient when faced with unfavorable conditions. Because there are so many types of rubber, we will focus on the common characteristics that help define rubber as being tough.

Topics: Rubber Products, Urethane Coatings, Rubber

What Rubber is the Best for Mold Making?

When it comes to creating molds, selecting the appropriate type of rubber is crucial for achieving precise and durable results. When selecting the best rubber for mold making, it is vital to consider factors such as the desired level of flexibility, mold complexity, temperature resistance, and compatibility with the materials being molded. Here are some key factors to consider when selecting the best rubber for mold making:

Topics: Rubber Products, Sioux Rubber & Urethane, Custom Rubber Products

Urethane rubber is a versatile material known for its exceptional strength and durability, making it a popular choice for industrial and commercial applications. Sioux Rubber & Urethane, based in Sioux City, Iowa, is a leading manufacturer of high-quality urethane rubber products. Endurawear® Urethane is Sioux Rubber & Urethane’s proprietary blend of urethane rubber created specifically with our customers' needs in mind.

Topics: Sioux Rubber & Urethane, Urethane Products, Urethane Coatings

Urethane is derived from ethyl ester and is a crystalline compound that is colorless and odorless. Although urethanes are not quite rubber, they fall into a category of materials known as rubber. Urethanes fall somewhere between plastics and rubber. They are more pliable and softer than plastic, but also harder than rubber. It is these qualities that contribute to their exceptional load-bearing abilities, impact resistance, and overall toughness.

Topics: Urethane Products, Urethane