We have been creating rubber and urethane solutions for common abrasion and impact issues for 60+ years. We’ve served customers in a variety of industries and created solutions for countless applications. At this point, we often say “we’ve seen it all”, and it’s true -- we’ve seen a lot. Even so, we’re still surprised by some of the unique challenges that arise when our customers are met with a head-scratching abrasion, impact, or corrosion issue. Honestly, we love to be challenged! If you think you’ve got an issue that has no potential fix, you’d be surprised how creative we can be with size, durometer (hardness), and other rubber and urethane properties. Let’s take a look at some of the reasons to opt for a custom rubber solution for your unique issues.

We have been creating rubber and urethane solutions for common abrasion and impact issues for 60+ years. We’ve served customers in a variety of industries and created solutions for countless applications. At this point, we often say “we’ve seen it all”, and it’s true -- we’ve seen a lot. Even so, we’re still surprised by some of the unique challenges that arise when our customers are met with a head-scratching abrasion, impact, or corrosion issue. Honestly, we love to be challenged! If you think you’ve got an issue that has no potential fix, you’d be surprised how creative we can be with size, durometer (hardness), and other rubber and urethane properties. Let’s take a look at some of the reasons to opt for a custom rubber solution for your unique issues.

Cost

Often, customers are deterred from considering a custom solution because they presume that custom = prohibitively expensive. In many of our competitors, this is certainly true. However, we’re uniquely positioned to produce custom solutions that are incredibly reasonably priced. Because we are an in-house fabricator, we’re able to keep mold costs low. Our goal is always to present you with the most cost-effective solution that will truly save you time and money when applied. The price point of your custom product idea is likely more accessible than you think.

Endless Options

We are happy to list off the sizes and shapes of various substrates that we have created custom rubber and urethane solutions to protect...but that would be an incredibly long blog post. The truth is, the options are pretty endless. Urethane lends itself to almost unlimited applications. Our full line of castable and sprayable Endurawear urethanes provide the physical properties you need for your specific application. They vary in hardness, rigidity, and temperature range and can be bonded to most any metal, concrete, or wood surface.

Permanent Bonds

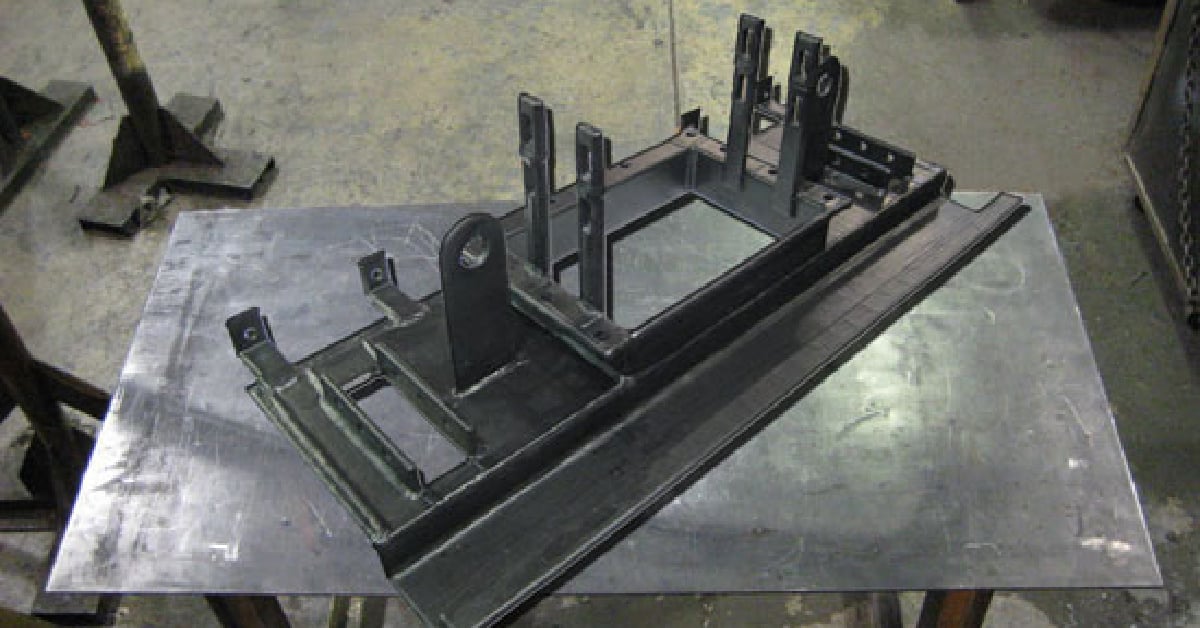

If you are looking for a permanent bond instead of a removable lining, we excel at this process. We can surface bond, encapsulate, and cover a large variety of substrates. If your part or piece is steel, stainless, aluminum, cast, galvanized, or even wood or concrete, we can permanently bond our Endurawear Urethane products to give you your desired outcome. For most of your urethane and metal assemblies, Sioux Rubber & Urethane can manufacture the metal inserts for you to provide a complete “one-stop” source for your finished part.

Custom products energize our team, and we love to put our expertise to use as we create unique solutions for your specific abrasion, corrosion, or impact issue. Curious about how we can help? Give us a call for a quote today!