Every year, Sioux Rubber & Urethane attends the GEAPS Exchange, an annual convention hosted by the Grain Elevator and Processing Society to help professionals in the worldwide grain industry make new connections, find solutions, and learn about new technologies. This year the event was hosted in Kansas City, and we sent Derek DeGroot, Jordan Langley, and Joe Wren to man our booth on the showroom floor.

Topics: Company News, Sioux Rubber & Urethane

Clamp Pads Decrease Damage to Material Handling. Here’s Why.

Some things are just meant to go together. Rubber and urethane, for one. Two things that never go together, though? Bare metal forklift clamps and inventory.

Topics: Clamp Pads, Rubber Products

The Sioux Rubber Idler Roller: How Grain Operators Become Smooth Operators

Sioux Rubber & Urethane was approached by a national grain processing company to help improve the lifespan of their steel idler rollers at their local soybean processing facility. Idler rollers provide a rolling service for the grain belts to glide on as they transfer grain at large installations; while they are easy to replace, the overall process and expense to do so was starting to add up.

Topics: Uncategorized

3 Ways the Tuff-Tube® Lining System is Reshaping the Ag Industry

There are many unpredictable elements to working in the seed and grain processing industry. Hail can decimate entire fields. Droughts can dry up yields. Failed equipment can eat into whatever profit margins there are left. While weather, weeds, and pests are often (if not always) out of our control, there are some factors against which we can predictably guard, and equipment wear and tear is one of them.

Topics: Tuff Tube, Urethane Products

The Water Bullet: Strong Under Pressure

There is never a dull moment at Sioux Rubber & Urethane. One moment we are curing our trademarked HawkPad for the cardboard packaging industry, the next moment we are developing rollers and spouts for agricultural equipment. And then there are days like today when we can talk about making water bullets and how they instantly, completely, and temporarily seal high-pressure fluid pipes.

Topics: Sioux Rubber & Urethane, Uncategorized, Water Bullet

Heading to New Frontiers: A Recap of the SuperCorr Expo

Sales Managers Derek DeGroot and Jordan Langley headed down to sunny Orlando, Florida last month to Sioux Rubber & Urethane’s first foray into the SuperCorr Expo, the largest gathering of vendors and corrugated solution seekers in the Western Hemisphere. They joined more than 300 industry suppliers and thousands of industry leaders from 70 countries for a four-day event spearheaded by the corrugated industry’s two leading associations, TAPPI and AICC.

Topics: Company News, HawkPad, SuperCorr Expo, Urethane Products

The Life Cycle of the HawkPad in 5 Steps

Since we introduced the HawkPad for our cardboard honeycomb packaging customers, we’ve been making more HawkPads than ever. As the premier press pad for commercial die-cutting applications, its unique ratio of multi-layered hardwood to custom-blended urethane gives it a hardness, thickness, and durability unlike any other press pad on the market.

Topics: HawkPad, Uncategorized

The Cutting Edge: How The HawkPad Revolutionized This Protective Packaging Company

Sioux Rubber & Urethane recently partnered with one of the largest paper-based honeycomb manufacturers in the U.S. to pit the HawkPad against one of the toughest die-cutting environments in the industry.

Topics: HawkPad, Rubber Products, Sioux Rubber & Urethane, Urethane Products

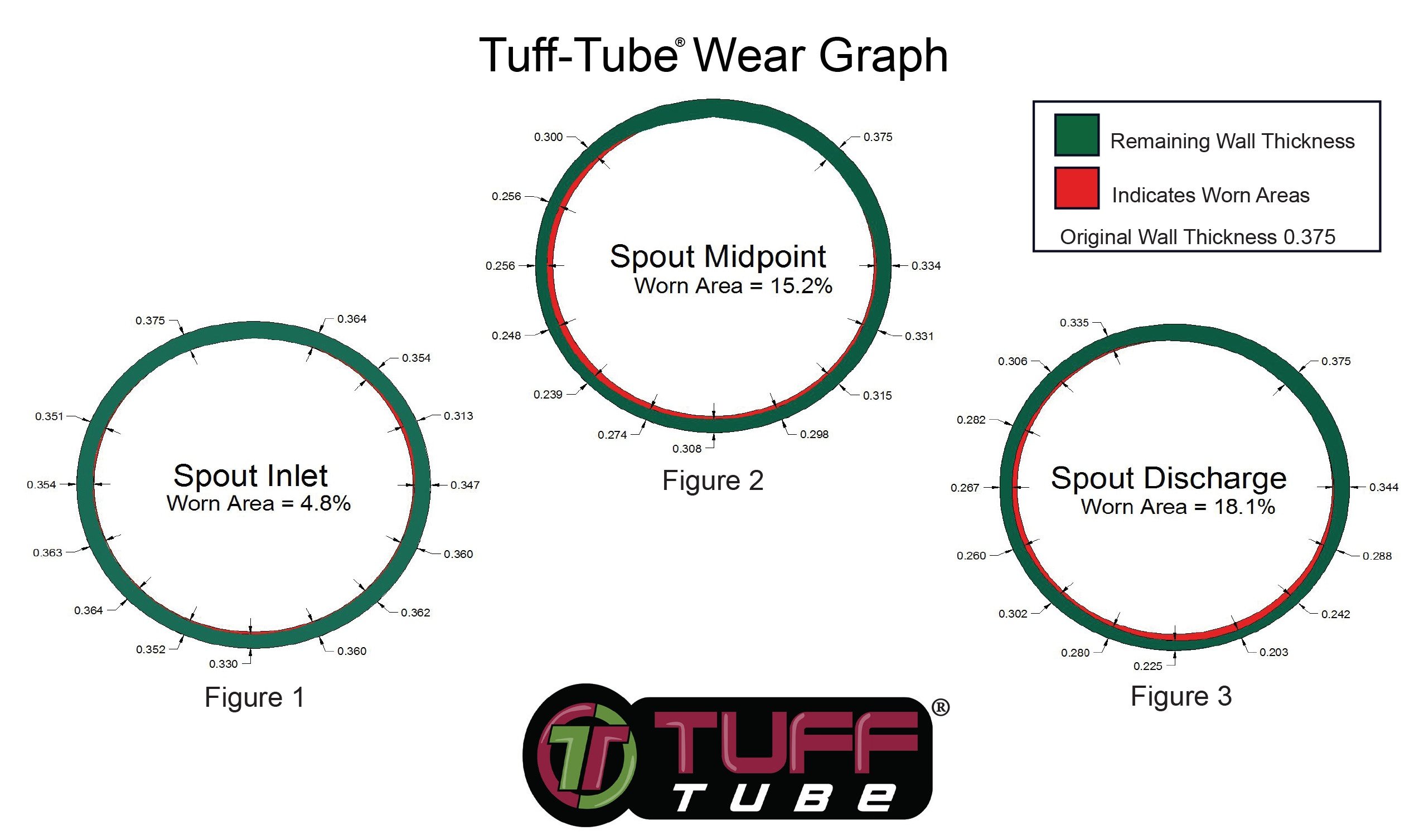

Initial field testing of Tuff-Tube began with an 8” diameter Tuff-Tube at an Iowa soybean processing facility in 2005. At the start of the test period, this facility was wearing completely through a standard ¼” urethane sheet being used as a traditional bolt-in spout liner each year and at times also wearing through the steel spouting itself. Designed specifically for ease of installation, the patented Tuff-Tube is made of a custom blended urethane specifically formulated for these types of abrasive applications.

The Tuff-Tube test installation was so successful, that after 3 years of the test the international soybean processing company that allowed us to do the testing mandated that Tuff-Tube be installed in all its facilities during any new construction, remodel, or changes to current facilities.

In 2015, after handling over 22 million bushels of soybeans and a decade in service, the original Tuff-Tube was pulled from testing for a comprehensive wear examination. The cross sectional graphics (figures 1, 2 and 3) show the minimal amount of wear (thickness lost) that occurred after 22 million bushels of soybeans. As seen in the graphics, over 50% of the thickness of the Tuff-Tube remains at the thinnest section of the piece. 22 million bushels of soybeans and the Tuff-Tube still had more than half of its service life left!

Topics: Uncategorized

1-1/2” diameter Pipe-Yup, we can rubber line that!

Rubber lining is a skill that takes time, experience, and knowledge to perfect. Sometimes the most difficult projects are the smallest ones. Take, for example, the skill required to line 1-1/2” diameter pipe with rubber. The challenge comes into play with only having a working area of 1-1/2” diameter. At Sioux Rubber & Urethane we have the capability and the skill to rubber line even the smallest of pipes. We have a variety of premium rubbers that will meet your application requirements and with stand the most corrosive chemicals and abrasive materials.

Topics: Uncategorized