When your machines or equipment breaks down due to abrasion, impact or corrosion issues, you’re losing money. Daily wear and tear is common, but your equipment is only designed to take so much. When this happens, not only has production stopped but the costs quickly add up with repairs and downtime. We developed rubber and urethane products that take the daily abuse from abrasion, impact and corrosion, saving your equipment and protecting your materials. Better yet, when the rubber or urethane wears out, that’s all that needs to be replaced, saving you time and money.

3 Products that Fight Lost Productivity

Topics: Clamp Pads, HawkPad, Tuff Tube

We started our business more than 60 years ago based on the durability, impact and corrosion resistance of rubber. We knew this wonder material was the answer to so many abrasion issues that manufacturers and many other industries face.

Topics: Rubber, Endurawear

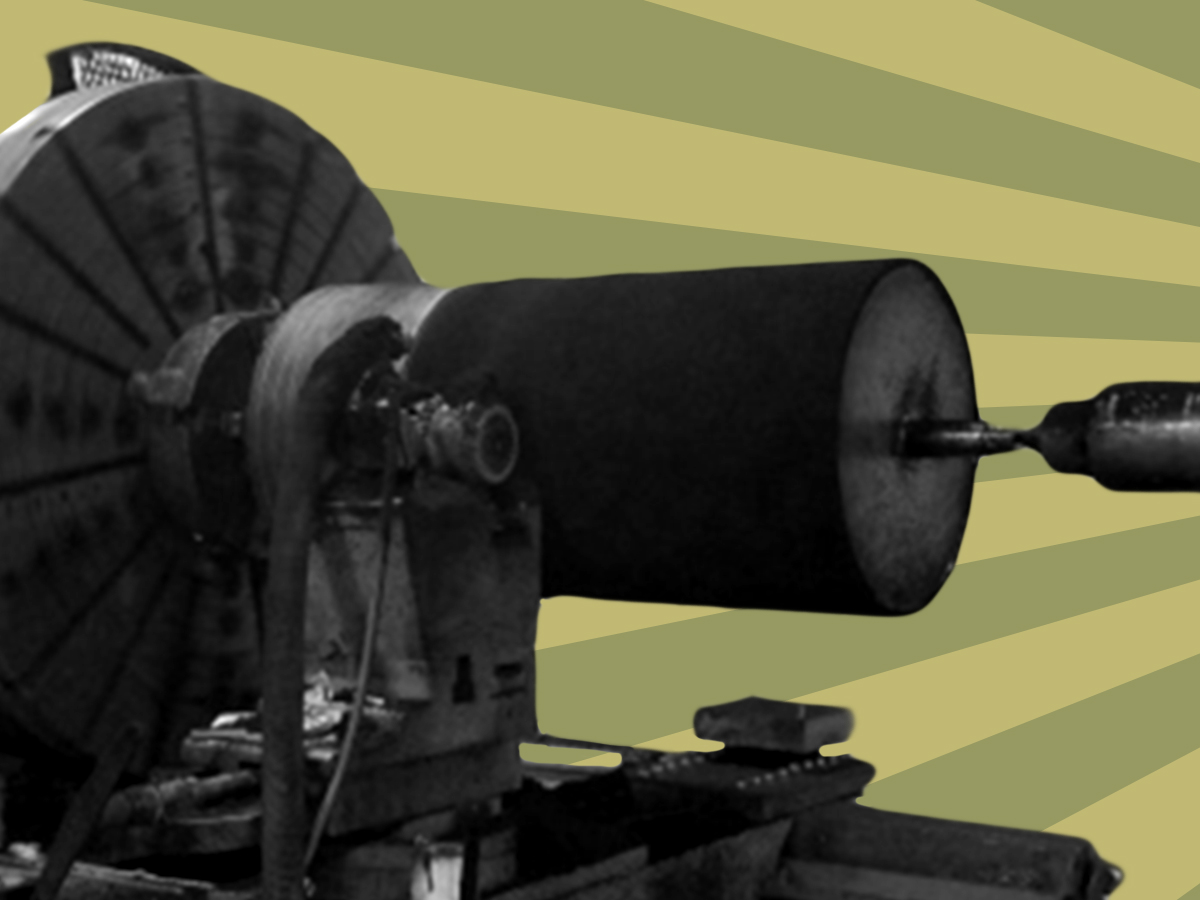

When material needs to be moved, a roller or a pulley is used. Simple machines have been used throughout history to make work easier, and among those are the wheel and axle (a rudimentary version of the roller) and the pulley. And because they’ve been around for so long, you may take for granted how much easier they make your job. These two tools make it possible to move large, heavy pieces of equipment but are also used in delicate applications, and rubber and urethane make them work even better.

The Hard and Soft of Urethane and Rubber

Urethane and rubber are amazing materials. They are used in a variety of products from footwear and insulation to rubber bands and tires. We use urethane and rubber for coatings, coverings, and molded products because it is so great at absorbing impact, reducing abrasion and resisting corrosion. One of the reasons urethane and rubber are so versatile is due to their varying degrees of durometers.

Topics: Urethane, Urethane Liners

At Sioux Rubber, we solve problems. The innovative products we offer are designed with one goal in mind: to help your business run smoothly. Within a wide variety of industries, from manufacturing to agriculture, equipment withstands a significant amount of wear and tear. When steel meets steel, day after day, hour after hour, it is just a matter of time before your operations are halted due to mechanical failures caused by steel-on-steel friction.

Topics: Abrasiplate

'Tis the Season for Recovered Clamp Pads!

The holiday season is here and if you’re looking for a gift that’s appreciated by your employees and protects your bottom line, you need to put recovered clamp pads on your list. You put your forklift to work all year long carefully moving around boxes and paper rolls without scratching, crushing or dropping them. It is likely that the clamp pads you use are worn, torn and simply not pulling their weight anymore. Instead of spending way more than you need to for a completely new pair, let us recover them.

Sioux Rubber & Urethane has been producing quality impact, corrosion abrasion-resistant products since 1958. We still use the same rubber faceplate today. Why? Because when we design or create a product, we make sure it lasts.

Urethane is one of the best materials available to cover and protect a piece of machinery. Urethane or polyurethanes mimic the traits of both plastic and rubber to offer the best in abrasion control and impact resistance. It is easy to use, has excellent wear resistance and can be poured, sprayed and brushed on almost any surface. Our urethane is a special blend we call Endurawear. This blend has been formulated specifically for our customers to provide excellent impact and abrasion resistance. We use urethane for a number of applications, including our liners.

Steel has many great properties – formability, durability, strength and thermal conductivity – but it isn’t resistant to abuse. Over time impact from heavy-duty use, abrasion from sand, gravel, grain and other materials and corrosion from chemicals can take its toll, causing even steel to fail. When this happens, your machine goes down, costing money in both repairs and downtime. That’s why we created our bolted liner product line, arguably one of the most heavy-duty lining systems on the market today.

Why Rubber is Best For Molded, Lined & Covered Products

Rubber is one of the most amazing products because it has an endless supply of uses and benefits. It is one of nature’s more durable and resilient materials. Originating from South America, it has been used for centuries before being manufactured for industry-use in the 1700s and then improved with the creation of synthetic SBR (Styrene-Butadiene Rubber). Why? Rubber is one-of-a-kind when it comes to flexibility, sturdiness and longevity; that’s why we use our Endurawear Rubber to coat, line and mold your machines and parts.

-1.jpg)